Products

Automatic auger filler washing powder rotary packing machine for stand up bag

Automatic auger filler washing powder rotary packing machine for stand up bag

Products Description

| Model | ZH-BG |

| System Output | >4.8 Ton/Day |

| Packing Speed | 10-40Bags/min |

| Packing accuracy | 0.5%-1% |

| Bag size | W:70-150mm L:75-300mm

W:100-200mm L:100-350mm W:200-300mm L:200-450mm |

| Bag type | pre-made flat pouch,stand up pouch,stand-up pouch with zipper |

Product Application

It is suitable for mixed packaging of milk powder, wheat flour, coffee powder, tea powder, bean powder, washing powder, spices, chemical powder, seasoning powder and other powder products.

Product Features

(1) It adopts Siemens advanced PLC, Schneider frequency converter and air switch automatic control, which has the characteristics of stability, reliability and high productivity.

(2) The main material in direct contact with food materials is food grade 304 stainless steel.

(3) No bag opening or filling, reducing product and bag waste and saving costs.

(4) When loading different bag sizes, the bag clamping distance can be changed automatically on the screen, which is easy to operate and has a wide range of uses.

(5) Allow punching holes in the top of the bag, optional feature.

(6) It can process prefabricated bags and paper bags of composite film, PE, PP and other materials.

(7) Suitable for nuts, puffed food, seeds, frozen food, powdered food, etc.

(8) Easy to control and save manpower.

Product detail

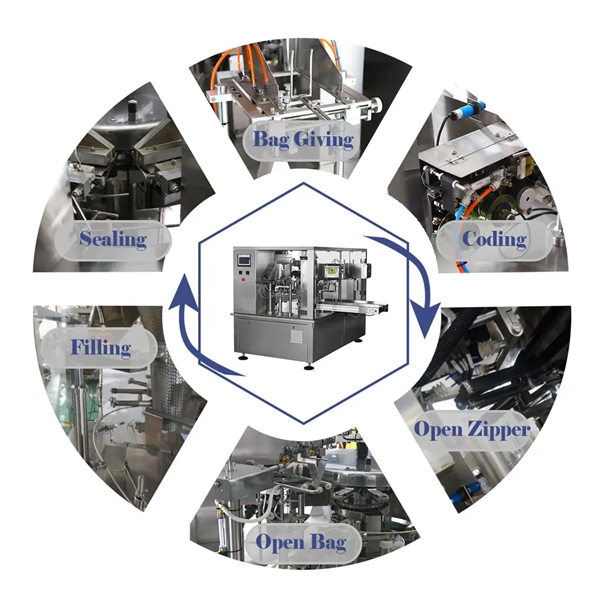

1. Bag release device: place bags horizontally or vertically, with intelligent control, easy operation and stable operation.

2. Date Printer: Print manufacturer/expiration date, up to 3 lines.

3. Zipper opening: Open the zipper of the bag.

4. Bag opening device: open the bag and fill the material into the bag.

5. Blanking device: high precision

6. Dust removal device: remove excess dust from the bag, so that the material can enter the bag better.

7. Heat sealing and cold sealing: net pattern or straight pattern

8. Electric box: Relays, temperature control meters, etc. use well-known component brands, and the quality is guaranteed.