Products

Automatic frozen fruit rotary pouch doypack packing machine

1.Application of Machine

It is suitable for weighing grain, stick, slice, globose, irregular shape products such as candy, chocolate, jelly, pasta, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, nuts, coffee bean, chips ,raisins, plum, cereals and other leisure foods, pet food, puffed food, vegetable, dehydrated vegetables ,fruits, sea food, frozen food, small hardware, etc.

2.Descriptions of ZH-BG10 Rotary Packing System

|

TECHNICAL SPECIFICATION

|

|||

|

Model

|

ZH-BG10

|

||

|

Packing speed

|

30-50 Bags/Min

|

||

|

System Output

|

≥8.4 Ton/Day

|

||

|

Packaging Accuracy

|

±0.1-1.5g

|

||

|

TECHNICAL FEATURE

|

|||

|

1. Material conveying, weighing, filling, date-printing, finished product outputting are all completed automatically.

|

|||

|

2. High weighing precision and efficiency and easy to operate.

|

|||

|

3. Packaging and pattern will be perfect with pre-made bags and have the option of zipper bag.

|

|

SYSTEM CONSTRUCTION

|

|||

|

Z Shape bucket elevator

|

Raise material to multi weigher which controls the start and stop of the hoister.

|

||

|

10 heads multi weigher

|

Used for quantitative weighing.

|

||

|

Platform

|

Support the 10 heads multi weigher.

|

||

|

Rotary packaging machine

|

Pack the material with high speed. And data printed, seal and bag cut are completed.

|

||

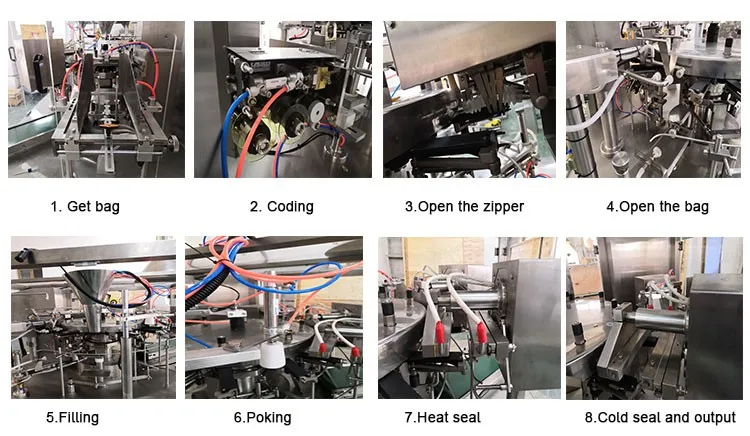

Working Process

1.Multihead weigher finished weighing,then rotary packing machine go on.

2.Premade bags are turned into flat pouch,stand- up pouch,stand- up pouch with zipper.

More details about machine