Products

Automatic Inclined Conveyor VFFS Packaging Machine for Rice Coffee Nuts Salt

Applications:

Fully automatic vertical form fill and seal packaging machine is suitable for packaging high-precision, fragile products, such as pet food, fish feed, corn flakes, snacks, breakfast cereals, popcorn, rice, jelly, candy, fried granules, potato chips , beans, seeds, dried fruits, etc.

Applicable bags: pillow bags/back seal bags/flat bags, 3/4 side seal bags, patch bags/triangle bags, folding bags/square bags.

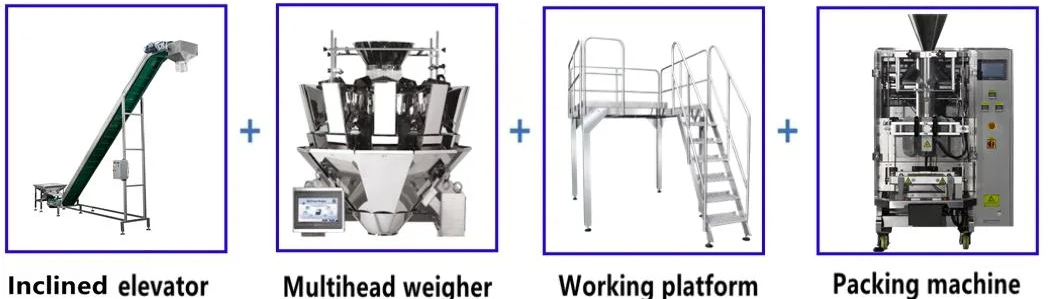

Working Processes :

Feeding–Conveying–Weighting–Forming ( Filling–Sealing ) –Finish Products Conveying

Features:

1. Chinese and English screen display, easy to operate.

2. The function of the PLC computer system is more stable and the adjustment of any parameters is more convenient.

3. It can store 10 pieces of data and it is easy to change the parameters.

4. Cut off the motor to pull the film, which is helpful for accurate positioning.

5. Independent temperature control system, accurate to ±1°C.

6. Horizontal and vertical temperature control, suitable for various composite films and PE film packaging materials.

7. Packaging methods are diverse, including pillow sealing, vertical sealing, punching, etc.

8. Bag making, bag sealing, packaging, and date printing are completed in one step.

9. Quiet working environment with low noise.

Advantage:

1. Efficient: bag making, filling, sealing, cutting, heating, date/batch number can be completed in one go.

2. Intelligent: The packaging speed and bag length can be set through the screen without replacing parts.

3. Professional: independent temperature controller with heat balance function, which can adapt to different packaging materials.

4. Features: With automatic shutdown function, safe operation and film saving.

5. Convenience: low loss, labor saving, easy operation and maintenance.

Technical Data

| Model | ZH-BV |

| Packing Speed | 30-70 Bags/Min |

| System Output | ≥8.4Ton/day |

| Pouch Material | PP、 PE、 PVC、 PS、 EVA、 PET、 PVDC+PVC、 OPP+ CPP |

| Packing Accuracy | ±0.1-1.5g |

| Type of Bag Making | Pillow Bag/Stick Bag/ Gusset Bag |

Main details

|

Main System Unite |

Inclined conveyor | Feeding the product to multihead weigher. |

| Multihead weigher | Weighing your target weight. | |

| Working Platform | Supporting the multihead weigher. | |

| VFFS packing machine | Packing and sealing the bag. | |

| Take off conveyor | Finished bag conveying. | |

|

Other option |

Metal detector | Detecting the metal of the product. |

| Check weigher | Double checking the weight of finished bag. |