Products

Automatic Snacks Coated Peanuts Packing Machine Food Packaging Machine

Main feature:

1. The whole machine adopts 304 stainless steel high-precision structure, which is rust-proof and durable, and easy to operate and maintain.

2. All machines have CE certification.

3. Imported PLC full computer control system, color touch screen, easy to operate, intuitive and efficient.

4. Frequency conversion speed regulation makes bag making more convenient, smooth, simple and fast.

5. Imported servo film feeding system, imported color code sensor, accurate positioning;

6. Filling, bagging, date printing, and inflation (exhaust) can be completed in one go.

7. The drive system is simple, more reliable and easier to maintain.

8. All controls are realized by software, which facilitates function adjustments and technology upgrades and never lags behind.

9. Optional English or other language screen display, convenient and simple operation. Packaging speed and bag length can be set with one click.

Application:

Automatic filling and sealing machine is suitable for granule and powder, such as grains, tea, spices, coffee, etc.

Parameter configuration:

|

Technical Parameter |

|

| Model | ZH-300BK |

| Packing speed | 30-80 bags/min |

| Bag Size | W: 50-100 mm L: 50-200 mm |

| Bag Material | POPP/CPP,POPP/VMCPP,BOPP/PE,PET/AL/PE, NY/PE,PET/PET |

| Max Film Width | 300mm |

| Film Thickness | 0.03-0.10 mm |

| Power Parameter | 220V 50hz |

| Package Size (mm) | 970(L)×870(W)×1800(H) |

Main Part:

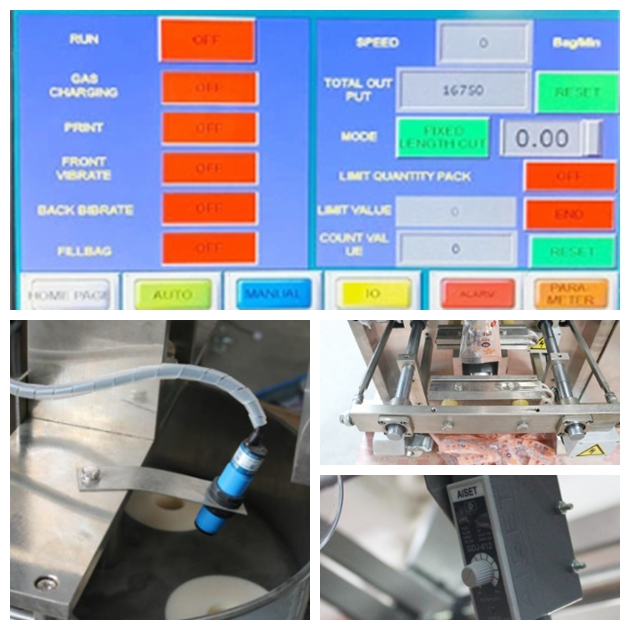

TOUCH SCREEN

1. Color touch screen

2. It is convenient to control the length of each bag and provides a highly sensitive photoelectric sensor system to realize automatic adjustment of the packaging film.

3. Various languages, Chinese, English, Russian, French, Korean, etc.

MESAURING CUP

1. Using volume conversion principle technology, simple and small error range

2. Automatic filling, automatically stops filling when full, no manual operation required.

3. Suitable for small particle products such as rice, sugar, beans, washing powder, candy, etc.

AUTOMATIC CUTTING DEVICE

1.This machine can produce standard center-sealed bags, 3/4 side-sealed bags or hem-sealed bags. Optional connection bags, opening devices, inflatable devices, etc.

EYE MARK

1.High-sensitivity optical lexic color mark tracking system, digital input of cutting position, making sealing and cutting more accurate. Reduce bag waste.