Products

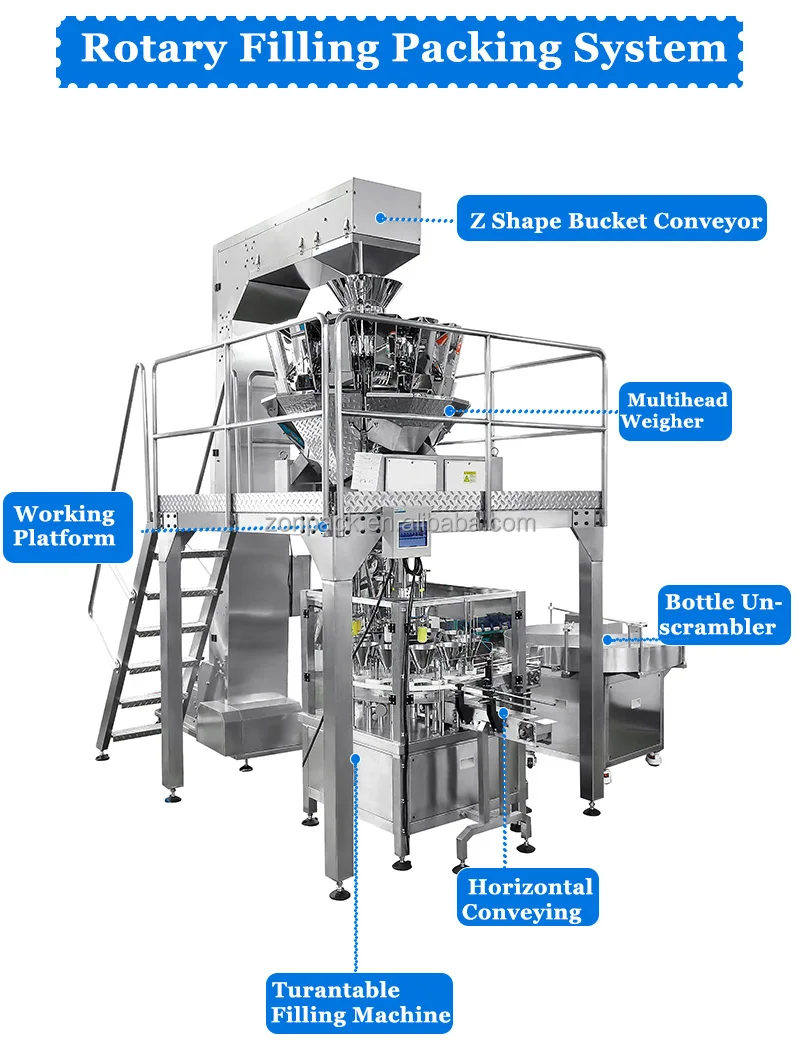

Bottle dry fruits filling machine automatic hazelnut walnut pine nuts can filling machine

Product Description

High Speed Weighing Filling Machine

Automatic granule weighing filling machine is commonly used in the food, chemical, and pharmaceutical industries to increase efficiency and accuracy in the packaging process.automatic granule weighing filling machine is used to measure and dispense a precise amount of granular or powder products, such as sugar, salt, spices, detergent, or small grains. The machine can accurately measure the weight of the product and adjust the filling amount to ensure consistency in each packaging.

Application

grain,stick, slice,globose, irregular shape products such as candy, chocolate, jelly,pasta, melon seeds, peanuts, pistachios,

almonds, cashews, nuts, coffee bean, chips and other leisure foods, raisins, plum,cereals, pet food, puffed food, fruits, roasted

seeds, small hardware, etc

almonds, cashews, nuts, coffee bean, chips and other leisure foods, raisins, plum,cereals, pet food, puffed food, fruits, roasted

seeds, small hardware, etc

Bottles and jars of various sizes

|

ZH-JR

|

ZH-JR

|

|

Can Diameter(mm)

|

20-300

|

|

Can Height (mm)

|

30-300

|

|

Max Filling Speed

|

55can/min

|

|

Position No

|

8 or 12 Press

|

|

Option

|

Structure/Vibration Structure

|

|

Power Parameter

|

220V 50160HZ 2000W

|

|

Package Volume (mm)

|

1800L*900W*1650H

|

|

Gross Weight (kg)

|

300

|

Sample Display

Main Function

1. Increased Speed: Features a rotary filling machine to boost production speed.2. Precision Capping: Equipped with a robotic capping system for precise and consistent capping.3. Labor Efficiency: Reduces labor requirements by automating the capping process.4. Enhanced Accuracy: Ensures high accuracy in filling and capping operations.

5. Advanced Automation: Incorporates cutting-edge technology for efficient and reliable performance.