Products

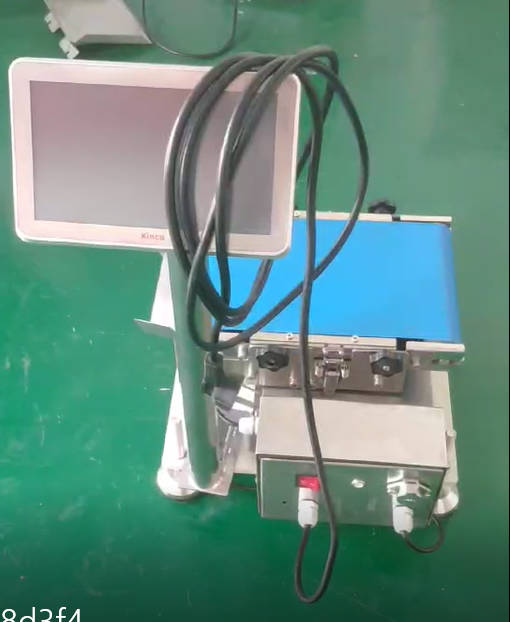

Cheap inspection machine checkweigher mini conveyor check weigher for small product for sale weighing

Application

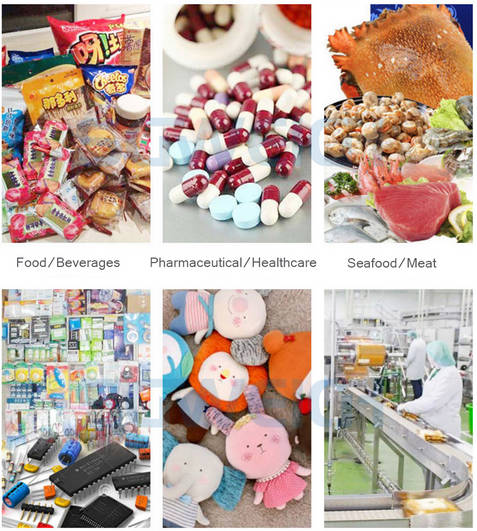

Check weigher controller are widely used to detect all kinds of tablets, granules, masks, thin cosmetics, small strips, fast weight, high precision, and can also be customized.

|

Technical Parameters

|

||||

|

Equipment name

|

Mini Check Weigher

|

|||

|

Speed

|

50bag/min

|

|||

|

Power

|

50W

|

|||

|

Total weight

|

30KG

|

|||

|

Weighing range

|

3-2000g

|

|||

|

Zero tracking

|

Automatic

|

|||

|

Application

|

Sauce packets, health tea and other materials of small packets

|

|||

Specifications are for reference only, this configuration can also be customized according to customer requirements. Our professional engineers will rigorously evaluate factors such as production line characteristics, specifications and environment, and design the most suitable checkweigher solution for your production line to meet the different needs of various complex production lines.

Main Features

High precision: imported high-speed weighing module and weight sensor ensure detection accuracy

Simple structure: The whole machine is made of stainless steel. The structure is simple. Easy to maintain and maintain

Easy to operate: Simple and intuitive touch screen operation Supports multiple languages (default Chinese and English)

Easy to connect: It can connect other equipment in the production line such as printer labeling machine and printer

Wide range of uses: For weight detection of bagged filling products, a variety of reject methods can be selected (push-type air blow type push can type, etc.)

Automatic feedback function: It can feed the front-end equipment signal in time to feedback the packing accuracy and adjust the feeding condition of the equipment connected to it.

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.