Products

Factory Price Automatic Round Bottle Labeling Machine In Packing Line

Application

Suitable for labeling round bottles, single label and double label can be pasted, and the distance between front and back double label can be adjusted flexibly. With tapered bottle labeling function; The perimeter location detection device can be used to label the designated position on the perimeter surface. The equipment can be used alone, also can be used with packaging line or filling line.

|

Technical Specification:

|

||||

|

Model

|

ZH-TB-300

|

|||

|

Labeling Speed

|

20-50pcs/min

|

|||

|

Labeling Accuracy

|

±1mm

|

|||

|

Scope of Products

|

φ25mm~φ100mm,height≤diameter*3

|

|||

|

The range

|

The bottom of the label paper:W:15~100mm,L:20~320mm

|

|||

|

Power Parameter

|

220V 50/60HZ 2.2KW

|

|||

|

Dimension(mm)

|

2000(L)*1300(W)*1400(H)

|

|||

Technical Feature

1. Simple adjustment, configuration before and after, left and right and up and down directions, plane inclination, vertical inclination adjustment seat, different bottle shape switch without dead Angle, simple and quick adjustment;

2. Automatic bottle division, star wheel bottle division mechanism, effectively eliminate the bottle itself error caused by the bottle is not smooth, improve the stability;

3. Touch screen control, man-machine interaction interface with operation teaching function, simple operation;

4. Intelligent control, automatic photoelectric tracking, automatic label detection function, to prevent leakage and label waste;

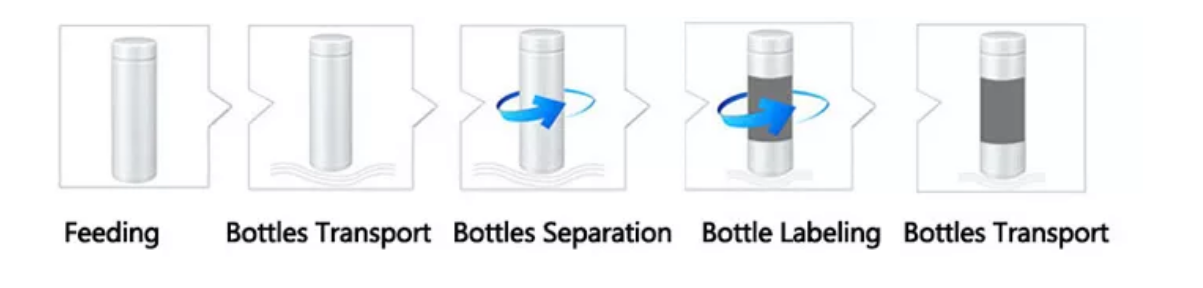

Working principle

The sensor detects the passing bottles and send a signal back to the control system.Atthe appropriate position, the system controls the label to be sent out and attached tothe suitable position .The product pass through the labeling device and the label isattached to bottles well.. Solid health, mainly made of stainless steel and senior aluminum alloy, solid quality, in line with GMP production requirements.