Products

High Accuracy Automatic 500g 1kg 2kg 5kg Pouch Big Bag Rice 4 head Linear Weigher Packing Machine

2.High accuracy and high speed.

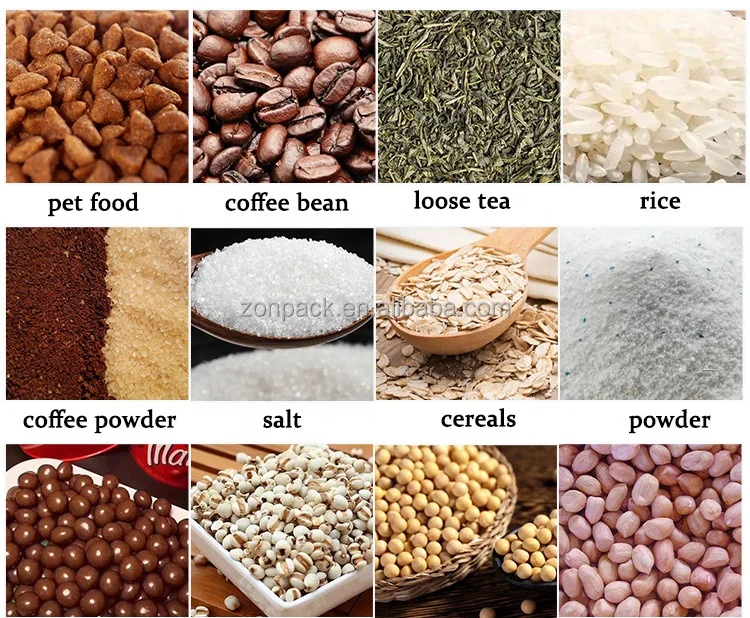

3.Applicable to a wide range of materials.

4.Applicable to the customer who without special requirements of packaging and material is widely used.

* High Accuracy Sweets linear Weigher have 100 preset programs for multiple tasks, and program recovery function can reduce

operation failure.

* Friendly HMI, similar with mobile phone icons, make operation more easily and simple.

* Abrasive cutting, exquisite welding, 304 stainless steel

*Stable modular control system.

If you have any weighing and packaging needs, please contact us and we will send you a weighing and packaging solution.

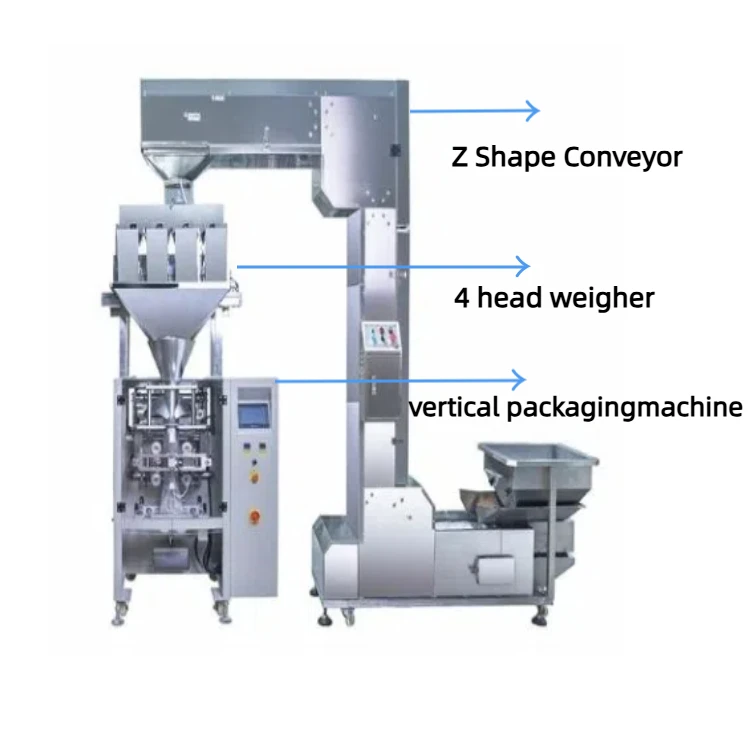

1.Linear weigher

We usually use Linear weigher to measure the target weight or count pieces.

It can work with VFFS,doypack packing machine,Jar packing machine.

Machine type:4 head, 2head ,1head

Machine accuracy :± 0.1-1.5g

Material weight range: 1-35kg

Right photo is our 4 heads weigher

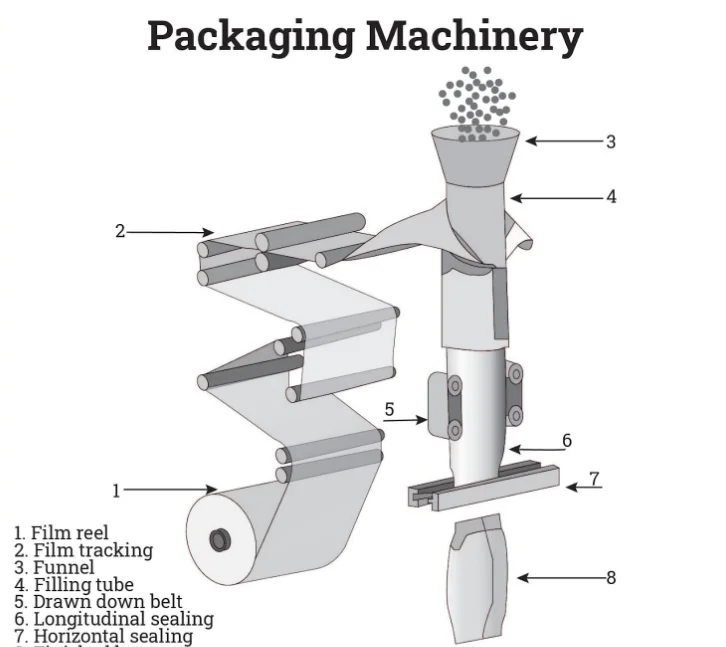

2. Packing machine

304SS Frame

VFFS Type:

ZH-V320 Packing machine: (W) 60-150 (L)60-200

ZH-V420 Packing machine: (W) 60-200 (L)60-300

ZH-V520 Packing machine:(W) 90-250 (L)80-350

ZH-V620 Packing machine:(W) 100-300 (L)100-400

ZH-V720 Packing machine:(W) 120-350 (L)100-450

|

Model

|

ZH-BL

|

|

System Output

|

≥ 8.4 Ton/Day

|

|

Packing speed

|

30-70 Bags / Min

|

|

Packing Accuracy

|

± 0.1-1.5g

|

|

Bag size(mm)

|

(W) 60-200 (L)60-300 for 420VFFS

(W) 90-250 (L)80-350 For 520VFFS

(W) 100-300 (L)100-400 For 620VFFS

(W) 120-350 (L)100-450 For 720VFFS

|

|

Bag type

|

Pillow bag, standing bag (gusseted), punch, Linked bag

|

|

Range of measuring (g)

|

5000

|

|

Thickness of film (mm)

|

0.04-0.10

|

|

Packing Material

|

laminated film such as POPP/CPP, POPP/ VMCPP, BOPP/PE,

PET/ AL/PE , NY/PE, PET/ PET,

|

|

Power Parameter

|

220V 50/60Hz 6.5KW

|

Main Features

For weighing machine

1.The amplitude of vibrator can be auto-modified for more efficient weighing.

2. High precise digital weighing sensor and AD module have been developed.

3. Multi-drop and succeeding drop methods can be selected to prevent puffed material blocking the hopper.

4. Material collecting system with function of unqualified product remove, two direction discharge, counting, restore default setting.

5. Multi-language operation system can be selected basing on customer’s requests.

For packing machine

6.Adopting PLC from Japan or Germany to make machine run stable. Touch screen from Tai Wan to make operation easy.

7. Sophisticated design on electronic and pneumatic control system makes the machine with high level of precision, reliability and stability.

8. Single or double belt pulling with servo of high precise positioning makes film transporting system stable, servo motor from Siemens or Panasonic.

9. Perfect alarm system to make problem solved quickly.

10. Adopting intellectual temperature controller,the temperature is controlled to ensure neat sealing.

11. Machine can make pillow bag and standing bag (gusseted bag) according to customer’s requirements. Machine also can make bag with punching hole & linked bag from 5-12 bags and so on.

Pre-Sales Service:

1.Provide packing solution according requirements

2.Doing test if customers send their products