Products

Leading Manufacturer for Liquid Sachet Chili Sauce Automatic Packaging Machine

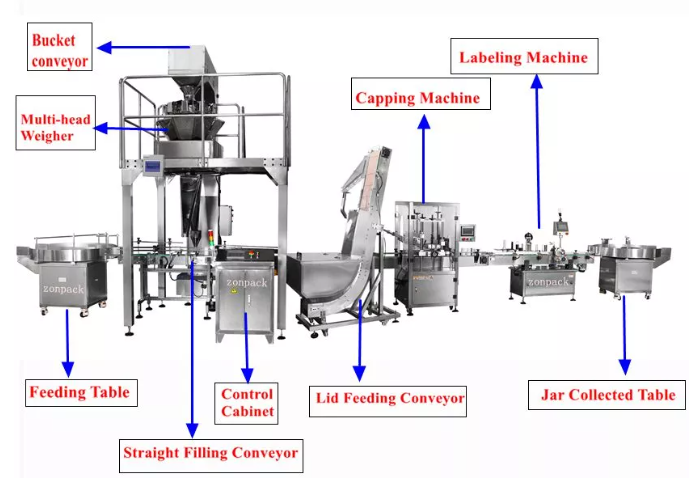

CAN JAR FILLING PACKING SYSTEM

Usually customer-oriented, we are ultimately focused on being not only one of the most reliable, trustworthy and honest suppliers, but also our shoppers' partner in becoming a leading liquid sachet chili sauce automatic packaging machine manufacturer's cooperation Guys, all comments and solutions would be greatly appreciated! Great cooperation can make both of us get better progress!

Usually customer-oriented, we finally focus on being not only one of the most reliable, trustworthy and honest suppliers, but also a partner of automatic packaging machine and jar can bottle packaging machine shoppers in China, our company has always adhered to the "quality for Based on honesty, honesty, customer first" business principles, has won the trust of customers at home and abroad. If you are interested in our products, please feel free to contact us for more information.

Technical Feature

1.Automatic control of feeding, modular mechanical structure of filling line, convenient maintenance;

2.High availability, adjust the width of filling line according to the box size within the applicable scope;

3.PLC control, man-machine interface, simple operation

bottles filling/case filling/irregular jars filling

Parameters

|

Working Process Of Whole Packing Line

|

|||

|

Item

|

Machine Name

|

Working Content

|

|

|

1

|

Feeding Table

|

Collect the empty jar / bottle /Case, make it line up, and waiting for the filling one by one

|

|

|

2

|

Bucket Conveyor

|

Feeding product into Multi-head weigher continuously

|

|

|

3

|

Multi-head Weigher

|

Use high combination from multi weighing heads to weighing or counting product with high accuracy

|

|

|

4

|

Working Platform

|

Support the Multi-head weigher

|

|

|

5

|

Filling Machine

|

We have a Straight filling machine and Rotary Filling machine option , Filling product into jar / bottle one by one

|

|

|

6

(Option)

|

Capping Machine

|

Lids will line up by conveyor , and it will capping automatically one by one

|

|

|

7

(Option)

|

Labeling Machine

|

Labeling for the Jar/ bottle /case due to your demand

|

|

|

8

(Option)

|

Date Printer

|

Print the date or QR code / Bar code by printer

|

|

detail

1.bucket conveyor

|

|

VFD control the speed. |

| 2. | easy to operate |

| 3. | save more space |

2.multihead weigher

|

|

10/14 head selection |

| 2. | multihead weigher display language can be customized according to customer requirements |

| 3. | Single weighing range is 10-2000g |

| 4. | high accuracy :0.1-1g |

| 5. | HBM sensor |

3.1 Rotray filling machine

| 1. | it with 10/12 filling cups option |

| 2. | Suitable for various products |

| 3. | Fast filling speed |

| 4. | jars/can is more suitable for filling |

3.2 straight filling line

| 1. | it is easy to adjust |

| 2. | more cheap than rotary filling machine |

| 3. | it will be more easy when it change other size jar/bottle/case |

4.capping machine

| 1. | lid feeding automatically |

| 2. | sealing have rotating seal and glanding seal option |

| 3. | more easy to adjust for different size of jars |

| 4. | high speed and accuracy of capping |

| 5. | sealing more closed |

5.labeling machine

| 1. | we have circular and square labeling machine option |

| 2. | labeling with high accuracy |

| 3. | speed more fast than manual |

| 4. | labeling more beautiful than manual |

| 5. | working more stable |

6.feeding table/colleated table

| 1. | it can be used for the empty jar feeding and finished product collection |

| 2. | VFD control the speed working more stable |

| 3. | diameter is 1200mm more space to collected jars |

| 4. | easy to adjust for different jars/bottles |

our story