Recently, our company successfully customized an automated mixed coffee powder and coffee bean packaging production line for an international coffee brand. This project integrates functions such as sorting, sterilization, lifting, mixing, weighing, filling, and capping, which reflects our company’s strong R&D strength and excellent customization capabilities. This production line not only significantly improves the customer’s production efficiency, but also achieves a win-win situation in cost control and product quality, which can be regarded as a technological innovation in the industry.

The entire production line includes the following equipment and functional modules:

Bottle collect table (bottling arrangement)

The first step of the production line, the bottle unscrambler automatically arranges the disordered bottles into an orderly arrangement to ensure the efficient operation of the subsequent process.

Bottle UV sterilizer

Before filling, the bottles are fully disinfected by the UV sterilizer to effectively eliminate potential microbial contamination and meet international food safety standards.

Elevator 1 (for lifting coffee powder, with built-in metal suction rod)

In order to save customers the cost of installing a separate metal detector, we innovatively embedded a metal suction rod device in elevator 1 to achieve the dual functions of material transportation and metal impurity detection, which not only simplifies the process but also saves equipment investment.

Granary (mixing coffee beans and coffee powder)

The granary is specially designed with a uniform mixing system to ensure that the coffee beans and coffee powder are fully integrated in the set ratio to achieve the ideal mixing effect.

Elevator 2 (transporting mixed materials)

Elevator 2 smoothly transports the mixed coffee beans and coffee powder to the weighing link. The conveying speed and stability are precisely adjusted to ensure the smooth operation of the production line.

14-head combination scale

The 14-head combination scale is one of the core equipment of the production line. It has high-speed and high-precision weighing capabilities. Even for mixed materials such as coffee powder and coffee beans, it can achieve a weighing accuracy of ±0.1 grams, providing reliable protection for the subsequent filling process.

Rotary filling machine

The filling machine adopts a rotary design, with fast speed and high precision. It can automatically fill the weighed mixed materials into the bottle to avoid material waste.

Metal detector

After filling, we added a metal detector to provide the last quality assurance for the finished product and prevent metal foreign matter from entering the finished product packaging.

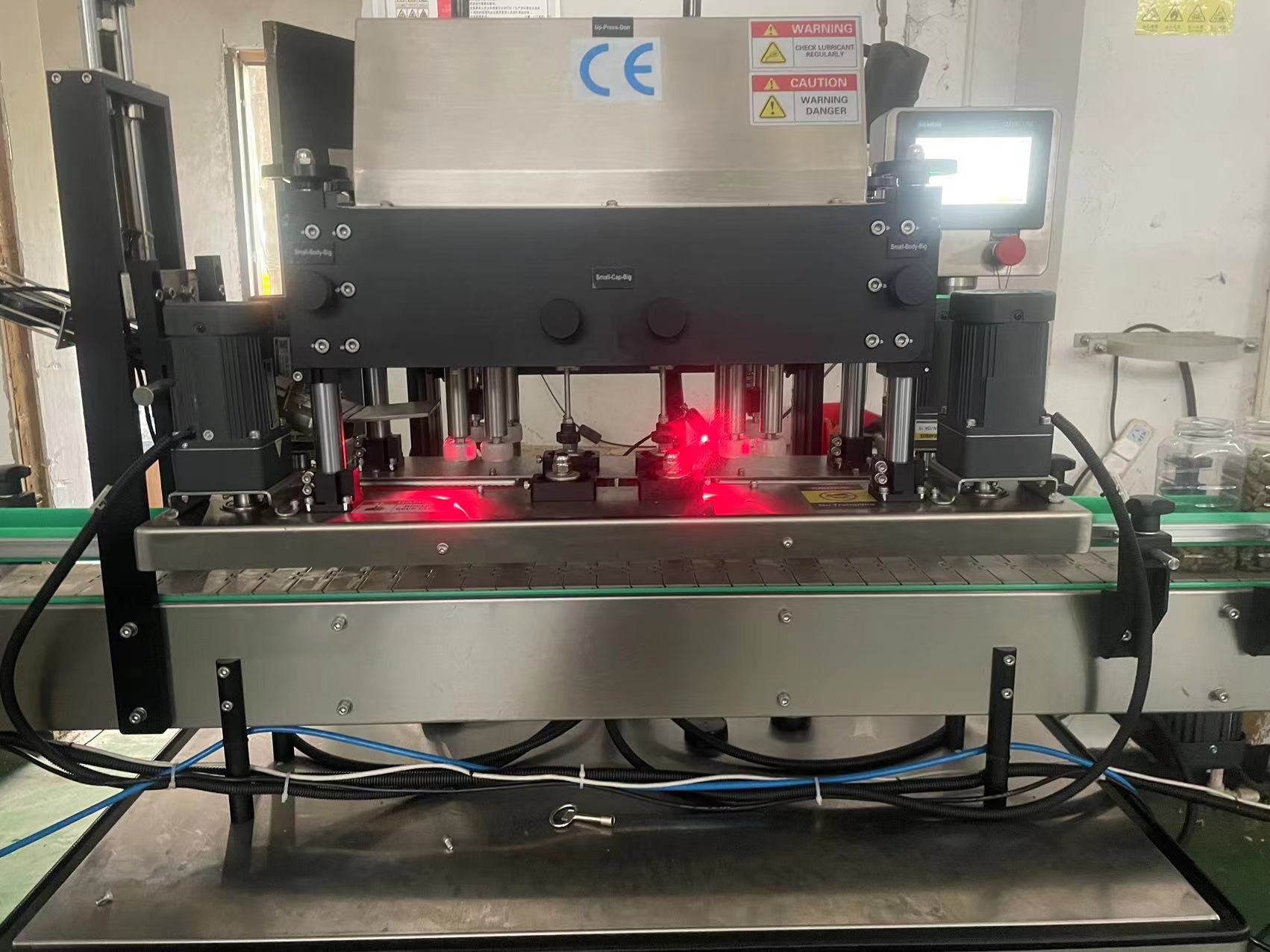

Capping machine

The capping machine automatically completes the capping and tightening of the bottle cap. The operation is fast and accurate, ensuring the sealing of the bottle cap and providing reliable protection for subsequent transportation and storage

Aluminum film machine

After capping, the aluminum film machine covers the bottle mouth with a layer of sealed aluminum film to increase the moisture-proof and fresh-keeping functions of the product and extend the shelf life.

Bottle unscrambler (bottle output)

The final bottle unscrambler will sort out the finished bottles after filling for easy packaging and boxing.

This customized project of automatic packaging production line for mixed coffee powder and coffee beans not only demonstrates our company’s profound technical accumulation in equipment design, production and integration, but also proves our customization ability and industry leadership. In the future, we will continue to uphold the “customer-centric” concept, continue to break through and innovate, provide more customers with efficient, intelligent and personalized packaging solutions, and help customers win the market competition.

Post time: Nov-29-2024