Products

ZH-TBJ-2510A Round bottle Double Sides labeling machine

Details

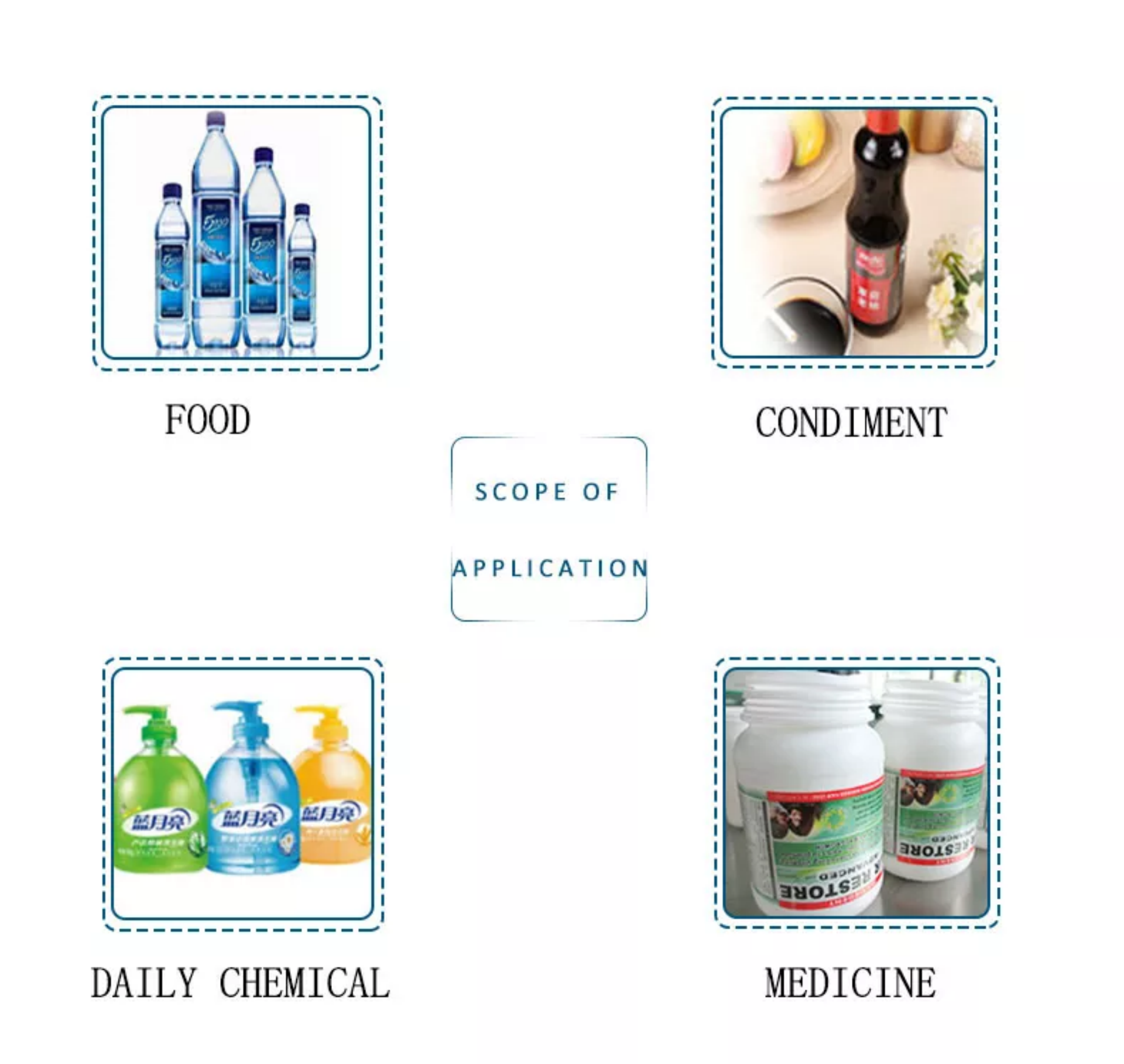

Application

It is suitable for single and double side labeling of similar products such as round, square and flat bottles in medicine, food, daily chemical and other light industries. One machine is multi-purpose, suitable for square bottle, flat bottle and round bottle at the same time. It can be used alone or online.

Technical Feature

1.The whole machine adopts a mature PLC control system, which makes the whole machine run stably and at high speed.

2.Universal bottle dividing device, no need to replace accessories for any bottle shape, quick adjustment and positioning.

3.The operating system adopts touch screen control, which is easy to operate, practical and efficient.

4.Double side chain correction device to ensure the neutrality of the material.

5.Special elastic top pressure equipment to ensure the stability of the material.

6.The labeling speed, conveying speed and bottle dividing speed can realize stepless speed regulation, which can be adjusted according to needs.

7.Labeling on round, oval, square and flat bottles of various sizes.

8.Special labeling device, the label is attached more firmly.

9.The front and rear sections can be optionally connected to the assembly line, and can also be equipped with a receiving turntable, which is convenient for the collection, arrangement and packaging of finished products.

10.Optional configuration (coding machine) can print the production date and batch number online, reduce the bottle packaging process and improve production efficiency.

11.Advanced technology (pneumatic/electrical) motor coding system, the printed handwriting is clear, fast and stable.

12.Air source for thermal coding machine: 5kg/cm²

13.Using special labeling device, the labeling is smooth and wrinkle-free, which greatly improves the packaging quality.

14.Automatic photoelectric detection, with no labeling, no label automatic correction or alarm automatic detection function, to prevent missed stickers and waste.

Working Principle

1.After the product is separated by the bottle separating mechanism, the sensor detects the product passing by, and sends the signal back to the control system, and controls the motor to send out the label at the appropriate position and attach it to the position to be labeled on the product.

2. Operation process: put the product (can be connected to the assembly line) -> product delivery (equipment automatic realization) -> product separation -> product testing -> labeling -> attach labeling -> collection of labeled products.

Technical Specification

| Model | ZH-TBJ-3510 |

| Speed | 40-200pcs/min (related to material and label size) |

| Accuracy | ±0.5mm |

| Product size | (L)40-200mm (W)20-130mm (H)40-360mm |

| Label size | (L)20-200mm (H)30-184mm |

| Applicable label roll inner diameter | φ76mm |

| Applicable label roll outer diameter | Maximum Φ350mm |

| Power | 220V/50HZ/60HZ/3KW |

| Machine Dimension | 2800(L)×1700(W)×1600(H) |